Hand Wrap Double Sphere Rubber Joints

Hand Wrap Double Sphere Rubber Joints

Hand Wrap Double Sphere Rubber Joints may not sound familiar to most people, but they are becoming increasingly important in certain industries as a cost-effective alternative to traditional fixed vulcanized rubber expansion joints. Often, in special circumstances, non-standard rubber expansion joints are required but the cost of making new molds or replacing molds can be prohibitively expensive. This is where hand-wrapped rubber expansion joints come in handy.

Description

Product Introduction

Hand Wrap Double Sphere Rubber Joints may not sound familiar to most people, but they are becoming increasingly important in certain industries as a cost-effective alternative to traditional fixed vulcanized rubber expansion joints. Often, in special circumstances, non-standard rubber expansion joints are required but the cost of making new molds or replacing molds can be prohibitively expensive. This is where hand-wrapped rubber expansion joints come in handy.

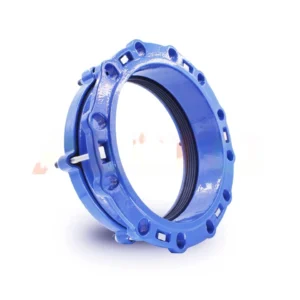

So, what are Hand Wrap Double Sphere Rubber Joints exactly, and how are they made? These expansion joints are made up of a cylindrical rubber component consisting of inner and outer rubber, fabric reinforcement, and steel rings. This component is wrapped by hand and then combined with loose flanges or parallel joints to create a flexible connector that compensates for axial, lateral, and angular movement of pipelines. These joints are then vulcanized at high temperatures and pressures to form a durable and reliable product.

The benefits of Hand Wrap Double Sphere Rubber Joints include their high elasticity, air tightness, resistance to corrosion, weathering, and radiation. They can reduce vibration and noise, and compensate for thermal expansion and contraction caused by temperature changes in pipeline systems. The size of the expansion joints can be customized according to specific requirements, making them highly versatile and widely used in various pipeline systems.

Whether you’re in the chemical, petrochemical, water treatment, or power generation industries, Hand Wrap Double Sphere Rubber Joints are an essential piece of equipment for your pipeline systems. Their cost-effectiveness, flexibility, and durability make them a popular choice for engineers and contractors alike. So, if you’re looking for a reliable and affordable solution for your pipeline expansion needs, look no further than Hand Wrap Double Sphere Rubber Joints.

Advantage

1. Balancing pipeline motion and vibration: Hand Wrap Double Sphere Rubber Joints can effectively balance pipeline system motion and vibration, prevent pipeline damage due to pressure and strain, and ensure the safe and stable operation of the pipeline system.

2. High wear resistance and aging resistance: This type of rubber joint adopts a manually wrapped outer layer, which can enhance the wear resistance and aging resistance of the rubber and extend its service life.

3. Good sealing performance: The double ball rubber joint of the handbag is fixed at both ends of the pipeline with metal flanges, which can reduce leakage and ensure the sealing performance of the pipeline.

4. Wide application range: This type of rubber joint is suitable for pipeline systems with media such as water, air, steam, and chemicals, and has high applicability and universality.

Reviews

There are no reviews yet.