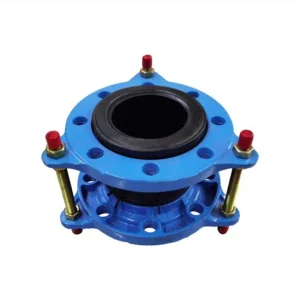

Food Grade Rubber Expansion Joints

Food-grade rubber joints are mainly used in food pipelines, so the material of food-grade rubber soft joints must be non-toxic and odorless.

Description

1. The food-grade rubber joints are made of natural rubber products based on silicone rubber. They pass the national testing standards for rubber used in food contact and reach the food-grade level.

2. The production environment of the workshop has certain requirements. Impurities, temperature and humidity in the air should be controlled within the range allowed by national standards, so as to ensure the 100% clean and hygienic products.

Advantages of food grade rubber expansion joint

1. Excellent stress tolerance

It is a combination of spherical structure with high internal pressure stability and strong special enhanced nylon, with excellent pressure resistance performance.Our flexible connectors exhibit excellent rupture resistance.

2.Super strong vibration, noise, impact absorption capacity

Our single sphere flexible rubber joints are designed to reduce vibration, noise and motion inherent in piping systems.Our joint installation will allow isolated devices to move freely, eliminating vibration and repelling sound prevalent in metal types of joint.

3.Compensates for greater elongation, compression, lateral and angular motion

Pumps, chillers, cooling towers, compressors, and piping systems can be deviated from calibration due to wear, load stress, and foundation block setup processes.Our flexible connectors, transverse, torsion and angular motion, prevent damage and eliminate costly downtime during factory operation.

| Working Pressure(Bar) | 10 | 16 | 25 |

| Burst pressure(Bar) | 30 | 48 | 55 |

| Vacuum(mmHg) | 400 | 650 | 750 |

| Application temperature | -15℃-115℃, Special can reach -30℃-250℃ | ||

| Application medium | Seawater, fresh water, hot and cold water, drinking water, domestic sewage, crude oil, fuel oil, lubricating oil, refined oil,air, gas, steam and granular powder. |

Reviews

There are no reviews yet.