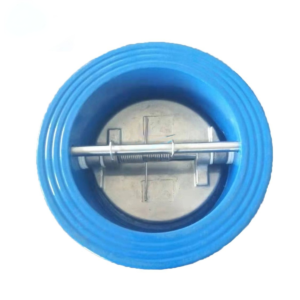

Ball Type Check Valve

Ball check valves are a type of valve that uses a

ball to stop fluid flow in one direction and allow it

in the other. They come in a variety of designs

including full bore, reduced bore, and non-return.

Ball check valves offer reliable backflow

prevention and are often used in applications

like pumps, compressors, and hydraulic

systems.

Description

Ball Type Check Valve Specification

• Valve Type: Ball check valve

• Valve Size: 1/2″ NPT, 3/4″ NPT, 1″ NPT, etc.

• Body Material: Brass, Carbon Steel, Stainless Steel, Plastic

• Ball Material: Brass, Stainless Steel, Chrome Plated Brass, Plastic

• Pressure Rating: 150 psi, 300 psi, 600 psi; etc.

• Temperature Rating: -200F to 4500F, -20’C to 2320C, etc.

• End Connections: Threaded (NPT, BSPT), Socket Weld, Flanged

• Flow Direction: Horizontal, Vertical Up, Vertical Down

• Checking Angle: 507 10′, 150, etc.

• Crack Pressure/Opening Pressure: 0_5 psi, 3 psil 5 psi, etc.

• Close Pressure: 0.25 psil 2 psil etc.

• Full Bore/Reduced Bore: Maximum CVValue or Pipe Size

• Body Desigm Two-piece, Three-piece, Monoblock

• Seat Material: PTFE, Delrin, Stainless Steel

• Certifications:

MSS SP-IIO, MSS SP-80, CE Marked

Ball Type Check Valve Features:

• Full Bore Design – Maximizes flow rate by allowing unobstructed flow when open. Reduces pressure drop.

• Compact Size – Smaller and lighter than flap type check valves. Takes up less space.

• Straight Through Flow – Allows smooth fluid flow in open position for reduced turbulence. Minimizes erosion and valve

wear.

• Fast Acting – Ball reacts quickly to reverse flow, providing tight shutoff Prevents backflow and slamming.

• Low Maintenance – No pin hinges or bearings. Self-cleaning and operates without lubrication.

• Weatherproof – Suitable for outdoor and submerged applications. Protects against weather damage.

• Variety of Materials – Available in brass, stainless steel, cast iron, and plastic. Offers corrosion resistance.

• Bi-directional Flow – Some ball check valve designs allow flow in either direction. Provides versatility.

• Easy Installation – Compact inline design enables easy integration into pipelines. Threaded or flanged ends available.

• Cost Effective – Simple mechanism with no moving parts makes ball check valves affordable. Good for budget

applications.

• Reliable Operation – Proven high cycle life with minimal wear. Handles frequent system operation.

Ball Type Check Valve Applications:

• Pumps – Used to prevent backflow and protect pump impellers from reverse rotation. Useful in water pumps, booster

pumps, centrifugal pumps.

• Compressors – Installed on the discharge line to hold pressure in the system when the compressor cycles off.

• Hydraulic Systems – Prevents reverse flow and loss of pressure in hydraulic circuits. Used in cylinders, motors, presse

• Steam Lines – Prevents condensate from backing up into steam lines, maintaining steam quality.

• Chemical Processing – Protects against backflow of corrosive chemicals. Handles high temps and pressures.

• HVAC Systems – Used in chillers, cooling towers, boilers to only allow one-way flow.

• Plumbing Systems – Added to supply lines as backflow prevention for fixtures and appliances.

• Wastewater Treatment – Prevents untreated water from reversing flow back into processes.

• Fire Protection Systems – Ensures water only flows one way in fire sprinkler lines to protect life and property.

• Irrigation Systems – Stops water from draining out when system is shut off and prevents contamination.

• Petrochemical – Useful in transferring corrosive or volatile fluids between storage tanks and processes.

Reviews

There are no reviews yet.