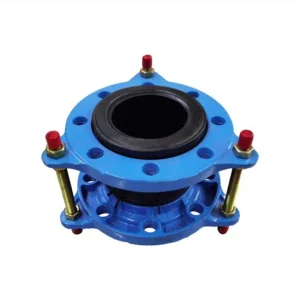

Quadruple Arch Rubber Expansion Joint

Quadruple Arch Rubber Expansion Joint

Quadruple Arch Rubber Expansion Joint uses four arches in the rubber section, providing good motion and flexibility, vibration control and damping, eliminating pipeline misalignment, thermal expansion, relieving stress, and reducing long pipeline noise. Four arches allow for greater movement than single arches, double arches, and three arches.

Description

Product Introduction

The Quadruple Arch Rubber Expansion Joint uses four arches in the rubber section, providing good motion and flexibility, vibration control and damping, eliminating pipeline misalignment, thermal expansion, relieving stress, and reducing long pipeline noise. Four arches allow for greater movement than single arches, double arches, and three arches.

Quadruple Arch Rubber Expansion Joint is a pipeline connection component made of rubber material, and its shape and length can be customized according to needs. It is a joint used to connect pipes or equipment with different diameters, and has good oil resistance, corrosion resistance, high pressure resistance, and high temperature resistance.

During the production process, the worker winds the rubber strip around a central tube and adds an appropriate amount of interlayer material during the winding process, making it more elastic and reliable. Afterwards, these wrapped rubber strips will be compressed and cured to form a complete rubber joint component.

Quadruple Arch Rubber Expansion Joint is suitable for connecting components in various pressure and temperature ranges of fluid conveying and processing equipment, such as water pumps, fans, compressors, pipelines, and valves. They are widely used in industries such as chemical, petroleum, electricity, light industry, pharmaceuticals, refrigeration, and metallurgy, and occupy important positions in industrial production and civil construction.

Advantage

1. Good oil resistance, corrosion resistance, high pressure resistance, and high temperature resistance, able to be used in complex industrial environments;

2. The length and appearance can be customized as needed, which can be suitable for different pipeline connection needs;

3. The production process is simple, the cost is low, and the production cycle is short;

4. It has good elasticity and reliability, which can effectively reduce vibration and noise at pipeline connections;

5. It has a wide range of applications and can be used in fluid transportation and processing equipment in industries such as chemical, petroleum, electricity, light industry, medicine, refrigeration, and metallurgy.

Reviews

There are no reviews yet.